Mirror & Gas Cell

high performance

Optical Technology The Gas Cell used in FTIR equipment is as much as necessary for a

durability can be withstand a gas for long time, It is manufactured from drawing design,

precise processing and special coating with compatibility of product.

Optical Technology The Gas Cell used in FTIR equipment is as much as necessary for a

durability can be withstand a gas for long time, It is manufactured from drawing design,

precise processing and special coating with compatibility of product.

For precise complex gas measurement

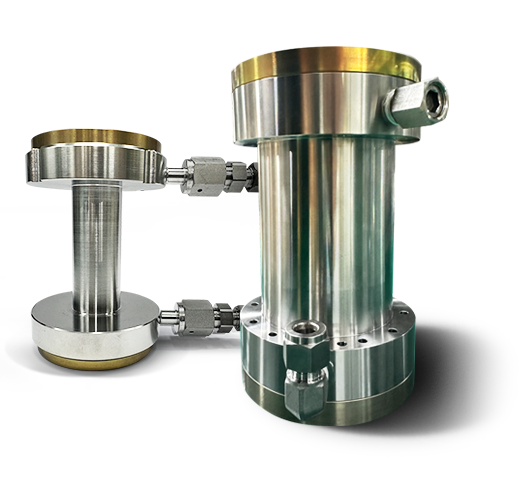

Optical Tech Gas

Cell A’ssy

For FTIR equipment and low concentration only.

High-strength Gas Cell for FTIR equipment only

It used in FTIR equipment only is designed and built to withstand corrosive gases and high temperature, pressure using special coating process inside.It can be set according to user settings, and it has products (pass length: 1M, 2M, 4.8M, 6M, 10M, 20M, and other user settings).

Long-Path Gas Cell (Metal)

| Body Material | SS300 or Al60 |

|---|---|

| Body Coating | None or Ni Plating |

| Mirror Coating | Au |

| Window Material | ZnSe or KBr |

| Window Demension(mm) | ⌀15, T=3 |

|

Pass Length Cell Volume |

1 M

0.38 L

2 M

0.4 L

5 M

0.47 L

6 M

0.47 L

10 M

2 L

20 M

4.1 L

※ Length and Volume can be customized |

Long-Path Gas Cell (Platic)

| Material | Plastic |

|---|---|

| Pass length | 970mm |

| Volume | 97cc |

| Working Temperature | 5~25℃ |

For precise complex gas measurement

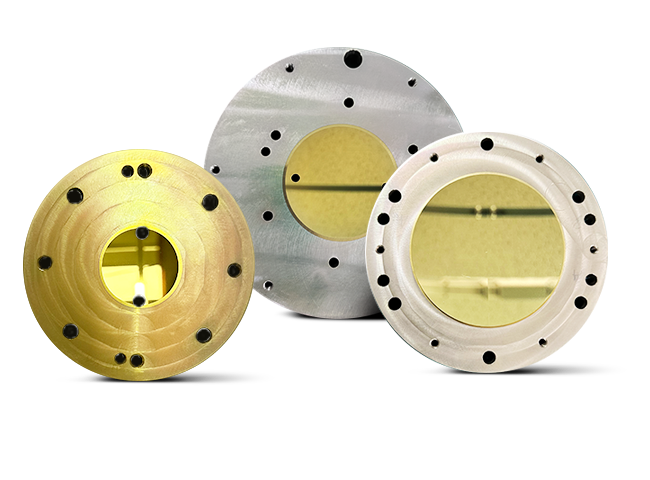

Optical Tech Mirror

Gas Cell only

(Replacement consumables)

Optical Tech Mirror Gas Cell Only (Replaceable Consumables)

It is the one of important parts thatdetermine the number of light reflections

inside Gas cell from FTIR equipment only.

It is replacement consumable and can be restored one

time depending on the product condition.

Optic Mirror (Metal)

| Material | Al 60 계열 |

|---|---|

| Coating | Au |

| Protective Coating | O |

| Ravg | >98% at 2~12μm |

Optic Mirror (Plastic)

| Material | Plastic |

|---|---|

| Coating | Au |

| Protective Coating | O |

| Ravg | >98% at 2~12μm |

- Mirror & Gas Cell Key Features

-

Corrosive, durable against high temperature and high pressure

- Since it is a product that should contain complex gas and toxic gas for several hours, it has been strengthened to withstand corrosion, high temperature, and high pressure through special coating and heat treatment.

-

Has compatible manufacturing technology depending on user`s equipment.

- Since compatibility according to FTIR equipment type is important, it has technical skills accordingly.